Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

What are the characteristics and challenges of the agricultural machinery manufacturing industry?

Characteristics:

Agricultural machinery operates in diverse geographical environments and working conditions. Key components often utilize a variety of metallic materials (such as wear-resistant steel and cast iron alloys), which must offer not only high strength and wear resistance but also good weldability and machinability.

As agricultural machinery evolves toward greater efficiency and intelligence, its structures are becoming increasingly larger and adopt modular design concepts to facilitate assembly, maintenance, and transportation. This places higher demands on the travel capacity of machining equipment and the stability of workpiece fixturing.

Core components of agricultural machinery typically involve a combination of multiple processes such as casting, welding, machining, heat treatment, and surface coating. This requires highly coordinated manufacturing workflows and stringent quality control throughout the entire production cycle.

Challenges:

Most agricultural machinery parts are made from high-strength or high-hardness materials and are produced in large batches. Cutting tools tend to wear out quickly during machining. Balancing tool life and processing efficiency is key to improving overall cost-effectiveness.

Large welded components are common in agricultural machinery. These parts are prone to thermal deformation during welding and subsequent machining. Controlling dimensional deviation requires optimized welding sequences, well-designed fixtures, and effective stress relief processes.

Some critical components feature complex three-dimensional surfaces. Their machining involves intricate tool path programming and relies on five-axis or multi-face machining technologies to achieve high-precision forming.

Core Equipment and Process Flow for Manufacturing Agricultural Machinery Parts

Core Equipment:

CNC Lathes, Vertical/Horizontal Machining Centers, Gantry Five-face Machining Centers, Surface and Cylindrical Grinding Machines, Automatic Sawing Machines, Complete Welding and Assembly Platforms, Coordinate Measuring Machine (CMM).

Process Flow:

Raw Material Cutting: Cutting or sawing processes are used to perform preliminary sizing of steel plates and profiles, ensuring machinability for subsequent processes.

Rough Machining: CNC equipment is employed for initial shaping and structural pre-machining, quickly removing excess material to form the basic contour of the parts.

Quenching and Tempering / Heat Treatment: Some parts undergo quenching and tempering or other heat treatment processes to improve hardness, toughness, and fatigue strength, thereby extending service life.

Precision Machining: Critical dimensions and assembly surfaces are finely machined and ground to ensure dimensional accuracy, tolerance control, and surface quality.

Welding / Assembly (if applicable): Professional positional welding is performed on modular or welded components, using dedicated fixtures to control deformation effectively.

Inspection and Testing: Each finished product must pass dimensional measurement, geometric tolerance verification, and assembly testing to ensure that functionality and accuracy fully meet customer drawings and operating conditions.

Technical Advantages of Equipment

The equipment layout is scientifically designed, covering all key stages from rough machining to finishing. This effectively reduces multiple setups and manual handling, improving processing efficiency. Through automated process path optimization and standardized fixture design, the per-piece machining cost is significantly lowered, providing customers with a more competitive pricing structure.

CNC equipment paired with high-precision grinding systems and real-time monitoring enables micron-level dimensional control and excellent surface finish quality. This is especially suitable for critical agricultural machinery parts requiring high fitting accuracy and sealing performance.

Vertical and horizontal machining centers, along with five-face gantry machines, offer multi-axis and multi-surface integrated machining capabilities. They can complete complex machining of multiple faces in a single setup, effectively avoiding repeated positioning errors. This is particularly advantageous for large, complex, or irregularly shaped parts, greatly enhancing production flexibility and delivery efficiency.

Through advanced toolpath programming and optimized cutting parameters, combined with the use of high-performance cutting tool materials, tool life on difficult-to-machine materials is significantly extended. This reduces frequent tool changes that disrupt process continuity, ensuring stable machining and consistent batch quality.

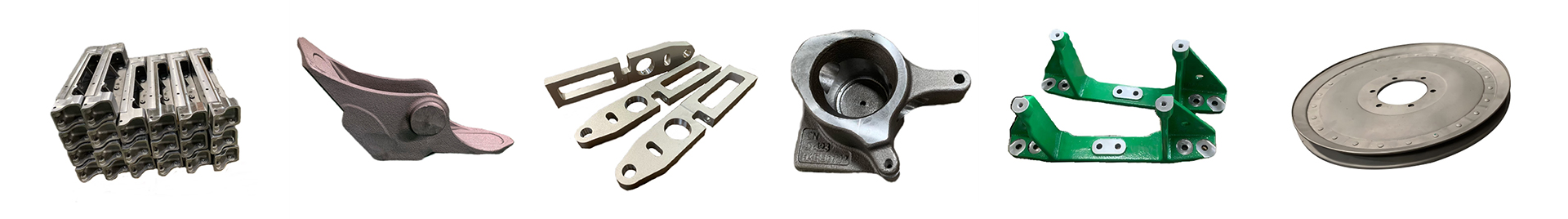

What parts can we manufacture for the agricultural machinery industry?

Housings

Traditional Shaft Universal Joints

Cast Steel and Cast Iron Connecting Components

Hydraulic System Parts: Piston rods, Cylinders, Valve Cores, Valve Seats

Harvesting Machinery Parts: Drum Teeth, Cutter Blade Holders

Brake System Parts: Connecting Shafts for Brake Shoes, Friction Surface Components of Brake Discs

Steering System Parts: Steering Knuckles, Ball Joint Seats

Irrigation Machinery Parts: Nozzle Holders for High-pressure Sprayers, Impellers for Water Pumps

Bearing and Transmission Auxiliary Parts: Bearing Rings, Synchronous Pulleys

Valves and Valve Assemblies: Valve Stems, Valve Seats, Valve Springs

Clutch Parts: Clutch Pressure Plates, Friction Plate Steel Cores, Shaft Components, Release Bearing Housings

Sensor Mounting Brackets